Groundbreaking Ideas to Slash Production Waste

In today's industrial landscape, waste reduction is crucial for achieving sustainability and improving operational efficiency. Reducing production waste not only saves resources but also cuts costs, boosts company reputation, and supports environmental conservation efforts. This article dives into innovative strategies to minimize waste in production processes, maximizing value and sustainability.

Understanding Production Waste

Before implementing waste reduction tactics, it's important to understand what production waste entails. Production waste refers to any materials or resources used in manufacturing that aren't part of the final product. Identifying various types of waste--such as excess inventory, defects, and overproduction--can help businesses target their efforts more precisely.

The Environmental and Economic Impact of Production Waste

Production waste significantly impacts both the environment and the economy. Factories producing excess waste contribute to greater landfill accumulation, while economic implications include unnecessary consumption of materials and increased disposal costs. Efficient waste management is critical to minimizing these effects.

Innovative Strategies to Reduce Production Waste

1. Lean Manufacturing

Lean manufacturing is a systematic method focused on minimizing waste without sacrificing productivity. Emphasizing

- Just-in-time manufacturing: This approach aligns raw-material orders with production schedules, minimizing inventory waste.

- Kaizen: Continuous improvement technique aiming for incremental changes to enhance efficiency and reduce waste.

2. Invest in Technology and Automation

Technology and automation can dramatically reduce waste through precision and consistency. By investing in cutting-edge technologies, businesses can streamline operations and minimize errors that lead to waste.

- 3D Printing: Reduces waste by building components layer-by-layer, minimizing scrap.

- AI and Machine Learning: Predicts supply chain needs, enhancing accuracy and reducing surplus orders.

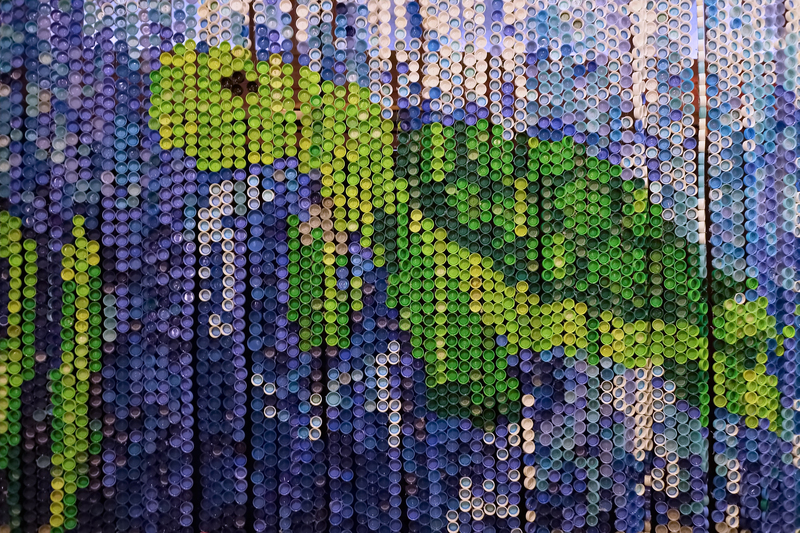

3. Adopt Circular Economy Principles

The circular economy concept revolves around maintaining materials' value by minimizing waste through strategies like reusing, refurbishing, and recycling products and materials.

- Waste-to-Resource Conversion: Transforming waste products back into valuable resources minimizes waste output.

- Product Life Extension: Designing products with modularity or reparability maximizes their lifespan, reducing waste.

4. Employee Training and Engagement

Educating and engaging employees enhances awareness and commitment to waste reduction initiatives. By cultivating a corporate culture centered on sustainability, businesses can drive impactful change.

- Training Programs: Implement training sessions addressing efficient practices and the importance of waste reduction.

- Incentive Schemes: Reward employees who actively contribute to waste reduction efforts.

Technology's Role in Waste Reduction

Advanced Manufacturing Technologies

Emerging manufacturing technologies have transformed how industries approach waste reduction. Advanced techniques promise unprecedented precision and optimization, translating directly into waste minimization.

- Robotics and Automation: Enhance production line efficiency, reducing defect rates and waste.

- Smart Factory Solutions: Internet of Things devices provide real-time data, empowering businesses with insights to decrease waste.

Case Studies of Effective Waste Reduction

Company A: Adopting Lean Principles

Manufacturing Company A streamlined its production using lean methodologies. By minimizing downtime and recalibrating production schedules, it saw a 30% reduction in waste within a year.

Company B: Circular Product Design

Company B embraced circular design by creating products conducive to reassembly and recycling. Through this shift, it cut down waste by promoting material reuse and establishing take-back programs.

Conclusion: The Path to Sustainable Production

To foster a sustainable future, manufacturers must continuously innovate and employ strategies to minimize waste. By embracing lean manufacturing, technology, circular economies, and employee engagement, companies not only contribute to environmental conservation but also distinguish themselves in a competitive market. Implementing these groundbreaking ideas can lead industries toward a zero-waste future, catalyzing both substantial economic benefits and lasting ecological impact.

As we move forward, it becomes imperative for organizations to continuously evaluate and iterate their strategies, ensuring they keep pace with advancements and environmental challenges. Only through persistent innovation and commitment can we hope to achieve truly sustainable production.